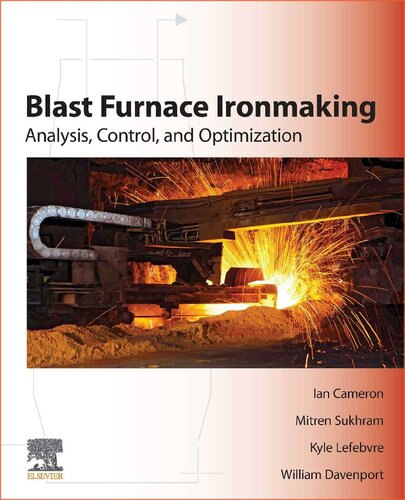

Blast Furnace Ironmaking: Analysis, Control, and Optimization Ian Cameron 1st Edition

$50.00 Original price was: $50.00.$25.00Current price is: $25.00.

Blast Furnace Ironmaking: Analysis, Control, and Optimization 1st Edition – Ebook Instant Download/Delivery ISBN(s): 9780128142271,0128142278,9780128142288, 0128142286

Product details:

- ISBN-10: 0128142286

- ISBN-13: 9780128142288

- Author: Ian Cameron; Mitren Sukhram; Kyle Lefebvre; William Davenport

Blast Furnace Ironmaking: Analysis, Control, and Optimization uses a fundamental first principles approach to prepare a blast furnace mass and energy balance in Excel™. Robust descriptions of the main equipment and systems, process technologies, and best practices used in a modern blast furnace plant are detailed. Optimization tools are provided to help the reader find the best blast furnace fuel mix and related costs, maximize output, or evaluate other operational strategies using the Excel model that the reader will develop.

Table contents:

1. The iron blast furnace process

2. Inside the blast furnace

3. Making steel from molten blast furnace iron

4. Introduction to the blast furnace mass balance

5. Introduction to the blast furnace enthalpy balance

6. Combining mass and enthalpy balance equations

7. Conceptual division of the blast furnace – bottom segment calculations

8. Bottom segment with pulverized carbon injection

9. Bottom segment with oxygen enrichment of blast air

10. Bottom segment with low purity oxygen enrichment

11. Bottom segment with CH4(g) injection

12. Bottom segment with moisture in blast air

13. Bottom segment with pulverized hydrocarbon injection

14. Raceway flame temperature

15. Automating matrix calculations

16. Raceway flame temperature with pulverized carbon injection

17. Raceway flame temperature with oxygen enrichment

18. Raceway flame temperature with CH4(g) injection

19. Raceway flame temperature with moisture in blast air

20. Top segment mass balance

21. Top segment enthalpy balance

22. Top gas temperature calculation

23. Top segment calculations with pulverized carbon injection

24. Top segment calculations with oxygen enrichment

25. Top segment mass balance with CH4(g) injection

26. Top segment enthalpy balance with CH4 injection

27. Top gas temperature with CH4 injection

28. Top segment calculations with moisture in blast air

29. Bottom segment calculations with natural gas injection

30. Raceway flame temperature with CH4(g) injection

31. Top segment calculations with natural gas injection

32. Bottom segment slag calculations – Ore, fluxes, and slag

33. Bottom segment slag calculations – With excess Al2O3 in ore

34. Bottom segment slag calculations

35. Bottom segment calculations – Reduction of SiO2

36. Bottom segment calculations – Reduction of MnO

37. Bottom segment calculations with pulverized coal injection

38. Bottom segment calculations with multiple injectants

39. Raceway flame temperature with multiple injectants

40. Top segment calculations with multiple injectants

41. Top segment calculations with raw material moisture

42. Top segment with carbonate fluxes

43. Top charged steel scrap

44. Top charged direct reduced iron

45. Bottom segment calculations with H2(g) injection

46. Top segment calculations with H2(g) injection

47. CO(g) injection into bottom and top segments

48. Introduction to blast furnace optimization

49. Blast furnace optimization case studies

50. Blast furnace rules of thumb

51. The blast furnace plant

52. Blast furnace proper

53. Blast furnace refractory inspection technologies

54. Blast furnace ferrous burden preparation

55. Metallurgical coke – A key to blast furnace operations

56. Blast furnace fuel injection

57. Casting the blast furnace

58. Blast furnace slag

59. Burden distribution

People also search:

modern blast furnace ironmaking

modern blast furnace ironmaking: an introduction (third edition, 2015)

blast furnace ironmaking

modern blast furnace ironmaking pdf

principles of blast furnace ironmaking

You may also like…

Engineering - Chemical Engineering

Technique - Light Industry

Engineering - Energy & Power Resources

Computers - Networking

Connected Vehicular Systems: Communication, Control, and Optimization 1st Edition Ge Guo

Technique - Electronics